Choosing the Right Barcode Scanner: 3 Key Factors to Consider

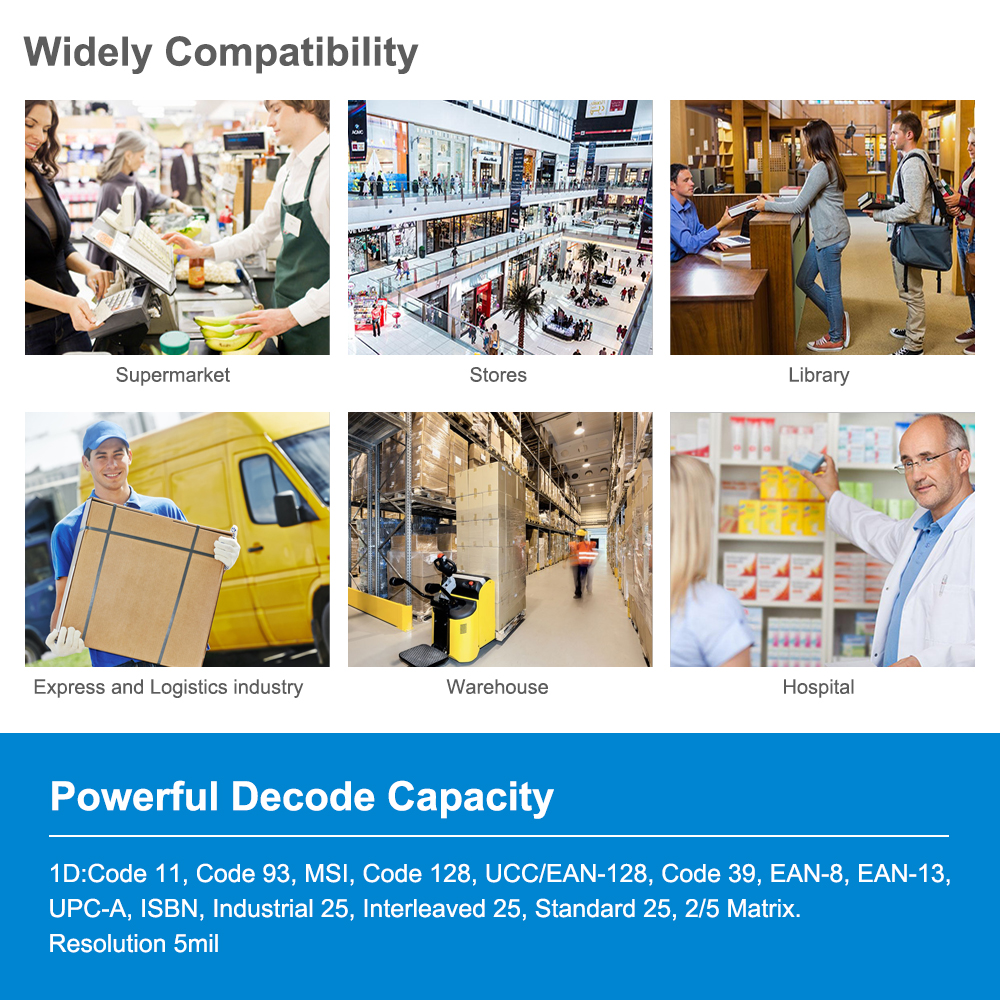

In the digital age, barcode scanners have become essential tools for applications like supermarket checkouts, hospital drug inventory, and factory production traceability. Choosing the right barcode scanner can double your productivity, while choosing the wrong one can lead to frequent malfunctions and disrupt your work. Three key factors should be considered when selecting a barcode scanner: whether the device can adapt to the working environment, whether the connection method matches the working mode, and whether the functions meet your actual needs.

First, consider the working environment's requirements for the device. In dusty and oily environments like factory workshops, it's crucial to choose a rugged barcode scanners. For example, a device with an IP67 rating for dust and water resistance can withstand a drop of two meters and operate normally in temperatures ranging from -30°C to +50°C. Given the unique environment of hospitals, the barcode scanners housing must withstand repeated wiping with disinfectants like alcohol and hydrogen peroxide, and must also be splash-proof to prevent contamination of the medical environment. barcode scanners used at supermarket checkout counters or in offices don't need to be quite as robust. A lightweight, durable, and basic model that's resistant to minor bumps and dings will suffice.

Secondly, choose the right connection barcode scanners type based on your work style. If you're using the device in a fixed location, such as a supermarket checkout counter or a logistics sorting point, a wired connection (like a USB port) is more stable, offers fast data transmission, and is less susceptible to interference. This is particularly suitable for the financial industry, which demands high data security. If you need to move the device around, such as taking inventory in a warehouse, you should choose a wireless barcode scanners. Bluetooth 5.0 technology ensures a stable connection within 50 meters and provides 12 hours of use on a single charge. Some devices also support switching between wired and wireless modes, allowing for both fixed use at the checkout counter and portable scanning of larger items, providing great flexibility.barcode scanners

Most importantly, the functionality must be tailored to the specific application scenario. When scanning medications in a hospital, the device must accurately recognize the UDI barcode scanners used for medical devices and have a silent function to avoid disturbing patients. Scanners used on factory production lines are even more demanding. They must be able to read DPM codes laser-engraved on metal surfaces and must scan at speeds of 300 times per second to keep pace. barcode scanners used in logistics warehouses need to see far, capable of scanning barcodes on top shelves over 20 meters away, and must perform reliably even in the low-temperature environments of cold storage.

Different barcode scanners types require different scanning technologies. 1D codes for ordinary products can be scanned with a basic laser scanner, while QR codes for mobile payments require an image-based scanner, which can read even slightly blurred or damaged barcodes. Industrial barcodes engraved on metal require specialized equipment that eliminates glare from the metal and accurately reads the information. Furthermore, the device's feel is crucial; a non-slip grip and a low-effort trigger design ensure workers can use it for extended periods without fatigue.

Simply put, choosing a scanner can be done in three steps: first, consider whether the work environment requires drop and water resistance, or corrosion resistance. Then, choose a wired or wireless scanner based on whether the work environment will be stationary or mobile. Finally, consider the type of barcodes to be scanned and whether any special features are required. For example, an automotive factory might want a wireless model that's drop-resistant, waterproof, and capable of scanning metal barcodes, while a pharmacy might need a silent model that can be disinfected and scan pharmaceutical barcodes.

Netum has 15 years of experience in barcode scanning and document imaging, focusing on providing stable, reliable, and technologically advanced data collection solutions to global enterprise clients. Our solutions are widely used in retail, logistics and warehousing, smart manufacturing, healthcare, government, and public services, effectively improving operational efficiency and data accuracy. If you have barcode solution needs, please contact us.

In addition to its diverse and high-performance product line,Netum also provides customers with comprehensive, high-quality services. It boasts a nationwide warranty system, ensuring rapid response and professional repairs. It offers 24/7 technical consulting to promptly resolve user issues. It can also tailor optimal scanning deployment solutions based on the scale and business characteristics of individual enterprises.