What is a portable barcode scanner?

A portable barcode scanner is a portable, lightweight barcode reading device whose core function is to quickly capture information from one-dimensional/two-dimensional barcodes. A portable barcode scanner illuminates the barcode with a light source (laser, LED, etc.), and uses a photosensitive element to convert the optical signals from the black and white stripes into electrical signals. After decoding, the data is transmitted to a computer, mobile phone, or other terminal via a wired (USB) or wireless (Bluetooth, 2.4G) connection. Portable barcode scanners are compact (typically weighing 30-400g), have long battery life (wireless models offer 8-12 hours of use per session), and are often waterproof and dustproof. They are suitable for mobile applications such as warehouse inventory, logistics sorting, retail checkout, and medical verification. They address the "immobility" of traditional fixed scanners and help improve mobile efficiency across various industries.

What are the use cases for portable barcode scanners?

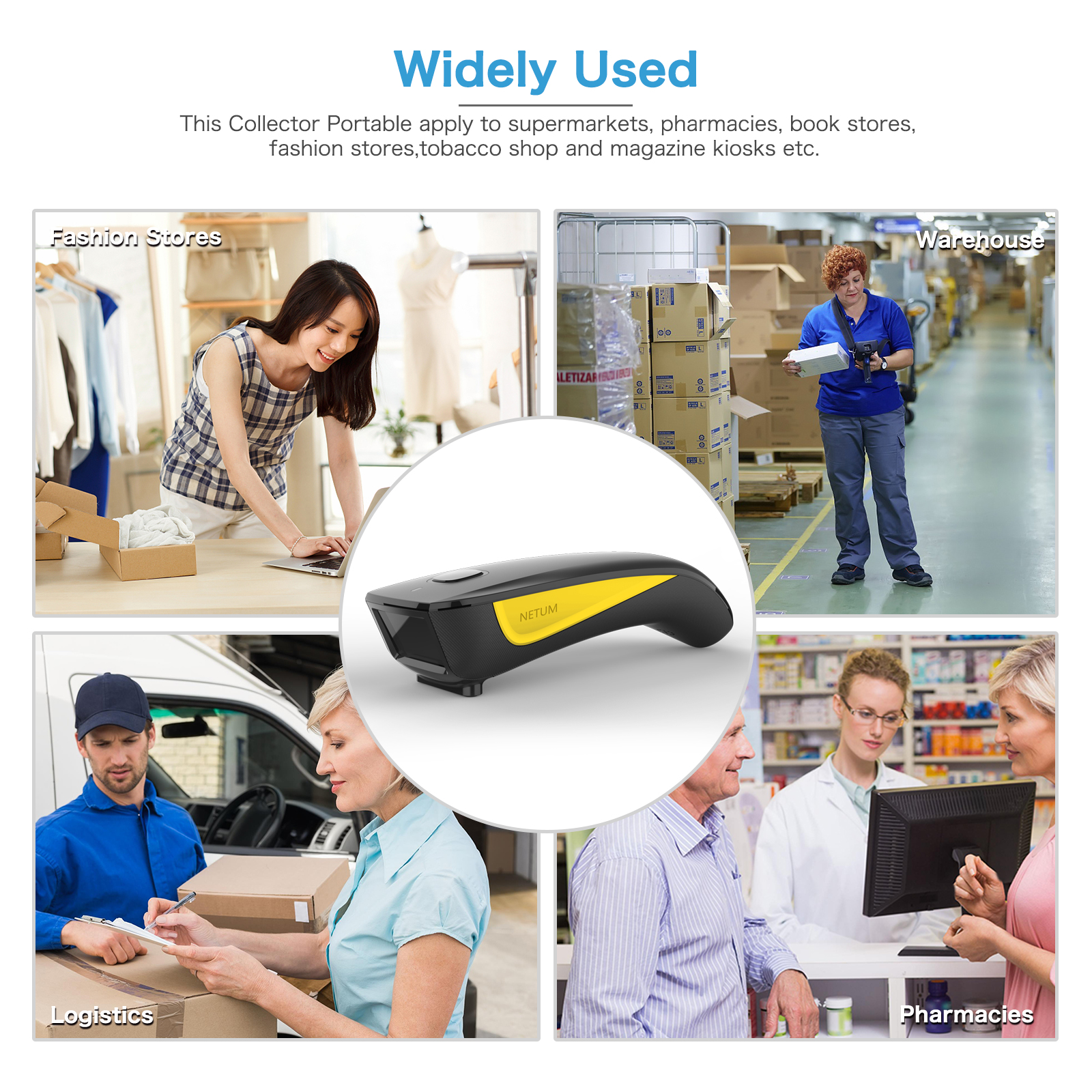

The core value of portable barcode scanners lies in their ability to break free from the constraints of fixed locations and enable mobile barcode collection. Therefore, they are widely used in industries requiring "anytime, anywhere" barcode scanning. The following are six core use cases and specific applications:

Logistics and express delivery: When couriers pick up packages, they use barcode scanners to quickly enter order information by scanning package barcodes. During warehouse sorting, workers use Handheld Barcode Scanner devices to scan package labels to accurately match delivery routes. During final delivery, they scan barcodes to confirm receipt, eliminating manual recording errors.

Retail and supermarket: Store employees can use handheld barcode scanners to conduct inventory checks on shelves, eliminating the need to carry products to fixed scanning areas and effectively tracking out-of-stock situations. At outdoor markets and temporary promotions, they can be paired with mobile checkout terminals for integrated "scan and pay," replacing traditional fixed checkout counters. When restocking products, barcodes on shelves and restocking bins are scanned to ensure accurate location matching.

In the healthcare industry, nurses use barcode scanners to scan patient wristband barcodes to quickly access medical records and medication information, avoiding patient identity verification errors. Pharmacists scan barcodes to verify drug barcodes against prescription information when dispensing medications to prevent mis-prescription. In medical equipment management, equipment barcodes are scanned to record usage and maintenance times, ensuring compliance.

In the manufacturing industry, production line workers use handheld barcode scanners to scan part barcodes to track their source and processing steps, enabling traceability of the production process. When finished products are shipped, they scan barcodes to record product information and shipment quantities, simultaneously updating inventory data. In quality inspection, barcodes are scanned to identify defective products and quickly link them to problematic batches.

In field inspection scenarios, power and communications engineers use portable barcode scanners to scan barcodes on equipment (such as utility poles and base station components) during inspections to record equipment operating status and inspection time. Property management personnel scan barcodes to register elevator and fire equipment maintenance status during building inspections. Librarians scan barcodes as they move between shelves to register book borrowing and inventory collections.

In the fresh produce and cold chain industry: When purchasing personnel inspect fresh produce at the production site, they use barcode scanners to record traceability information such as the origin and harvesting time of the ingredients. In cold chain warehouses, workers, even wearing thick work clothes, can flexibly hold barcode scanners to scan the barcodes of refrigerated goods and update cold chain inventory in real time. During store inventory, they can quickly identify the expiration dates of fresh produce by scanning barcodes to promptly handle near-expiry items.

What types of portable barcode scanners are there?

Portable barcode scanners can be categorized based on three core dimensions: scanning technology, connection method, and form factor. Each categorization has its own characteristics and suits different scenarios, as follows:

I. Classification by Core Scanning Technology

1. Portable Barcode Scanners: Laser Scanners

Laser scanners focus on high speed and long range and only support 1D barcode scanning. They offer scanning speeds of 200-600 scans/second, a range of 1-30 inches, and strong resistance to strong light interference, allowing them to operate stably in bright light environments such as warehouse skylights and outdoors. This type of scanner is often used for batch scanning of package barcodes during logistics sorting and for inventorying high-shelf merchandise in large retail warehouses. It's suitable for high-frequency 1D barcode processing.

2. CCD Barcode Scanner

CCD barcode scanners offer advantages such as low cost, long life, and no moving parts, reducing the likelihood of failure. However, CCD barcode scanners can only scan 1D codes and offer slightly inferior performance to laser scanners, with a scanning speed of 100-300 scans per second and a shorter scanning range of only 0.5-5 inches, requiring close proximity to the barcode. These devices are often used for close-range applications such as scanning product labels at convenience store checkout counters and scanning 1D codes on office documentation.

3. Imager Barcode Scanner

Imager barcode scanners are versatile devices capable of scanning both 1D and 2D codes, and can handle damaged, blurred, and tilted barcodes with an error tolerance rate exceeding 95%. With a scanning speed of 150-400 scans/second, these scanners can meet the needs of a variety of complex scenarios. The medical industry relies on scanning patient wristbands to verify information, and the electronics manufacturing industry relies on reading tiny QR codes on chips.

II. Portable Barcode Scanners by Connection Method

1. Bluetooth Connection Model

Bluetooth connection models require no additional receiver and can be directly paired with mobile phones, tablets, and other devices. They have a transmission range of 10-30 meters. Low-power models offer a single battery life of 8-15 hours, meeting all-day mobile operations. Bluetooth barcode scanners are suitable for retail employees using handheld devices for mobile checkout, and for field personnel scanning equipment barcodes and recording data during inspections.

2. 2.4G Wireless Model

2.4G wireless models require a dedicated USB receiver for use. They offer a longer transmission range, up to 50-100 meters in open air environments, are highly resistant to interference, and support simultaneous data transmission between multiple devices. This type of device is commonly used by sorters in large logistics warehouses scanning packages simultaneously, and by manufacturers scanning barcodes during cross-workshop inspections.

3. Wi-Fi Connection Model

The Wi-Fi connection model connects to the enterprise Wi-Fi network, allowing data transmission over any distance as long as it's within network coverage. It also supports offline storage, saving over 100,000 data items during network outages and automatically re-uploading them when connected. This device is suitable for chain supermarkets performing simultaneous inventory checks across multiple stores, and for large e-commerce warehouses aggregating scanned data from various areas.

4. Wired Connection Model

The wired connection model connects to computers and cash registers via a USB cable or other similar cable. Data transmission is stable and latency-free, and it doesn't require charging. It can operate continuously for extended periods, but its range is limited by the cable length (usually 1-3 meters). This type of device is commonly used for scanning documents at fixed checkout counters in supermarkets and at fixed workstations in offices.

III. Classification by Appearance

1. Handheld Barcode Scanners

Handheld barcode scanners feature a pistol-like grip design and weigh 150-300g, providing a stable and comfortable grip and suitable for long-term, high-frequency barcode scanning. These devices are commonly used by logistics sorters who continuously scan packages and by manufacturing workers who track barcodes on parts production lines. Industrial-grade models are also drop-resistant and can withstand the complex environments of warehouses and factories.

2. Pen Barcode Scanners

Pen-type devices are slender, like a pen, and weigh only 30-80g, fitting easily into pockets or pen bags. Their compact scanning heads allow them to reach into tight spaces, such as gaps between equipment and deep within shelves. They are suitable for workers in the electronics manufacturing industry who scan barcodes in gaps between equipment and for field electricians who read barcodes on equipment inside utility poles during inspections. Their only drawback is their relatively short scanning range.

3. Ring-Style Barcode Scanners

Ring-style barcode scanners fit on your finger like a ring and weigh 20-50g, allowing you to completely free your hands. Some models also feature vibration feedback, alerting you when a successful scan is successful. Ring-style barcode scanners are ideal for e-commerce pickers scanning barcodes while picking up items with both hands, and for fresh food delivery workers scanning and signing for packages as they pick them up, making operations more efficient.