Whether we scan a barcode to pay at the supermarket checkout, track a package at a courier, or access patient medical records at the hospital, we all rely on a crucial device: a 2D barcode scanner. It's more than just a "scanning tool," but rather a specialized device that rapidly converts the complex information contained in a 2D barcode into a digital signal. Compared to traditional scanners that can only read 1D barcodes, it can process massive amounts of data, including text, URLs, and images, making it a core entry point for modern information collection.

The operating principle of a 2D barcode scanner can be summarized as a "three-step process," ensuring high efficiency and accuracy. First, image acquisition occurs. A built-in CMOS image sensor and lens capture the barcode image. Some devices also feature an LED fill light, ensuring clear images even in dim or reflective environments. Next, the 2D barcode scanner enters the signal processing stage. A pre-processing module reduces noise, corrects distortion, and enhances contrast to eliminate environmental interference. Finally, the decoding output occurs. The decoding chip interprets the data based on the encoding rules of different 2D barcodes (such as the position detection algorithm for QR codes). The data is then transmitted to a terminal device such as a computer or mobile phone via USB or Bluetooth. The entire process takes only milliseconds.

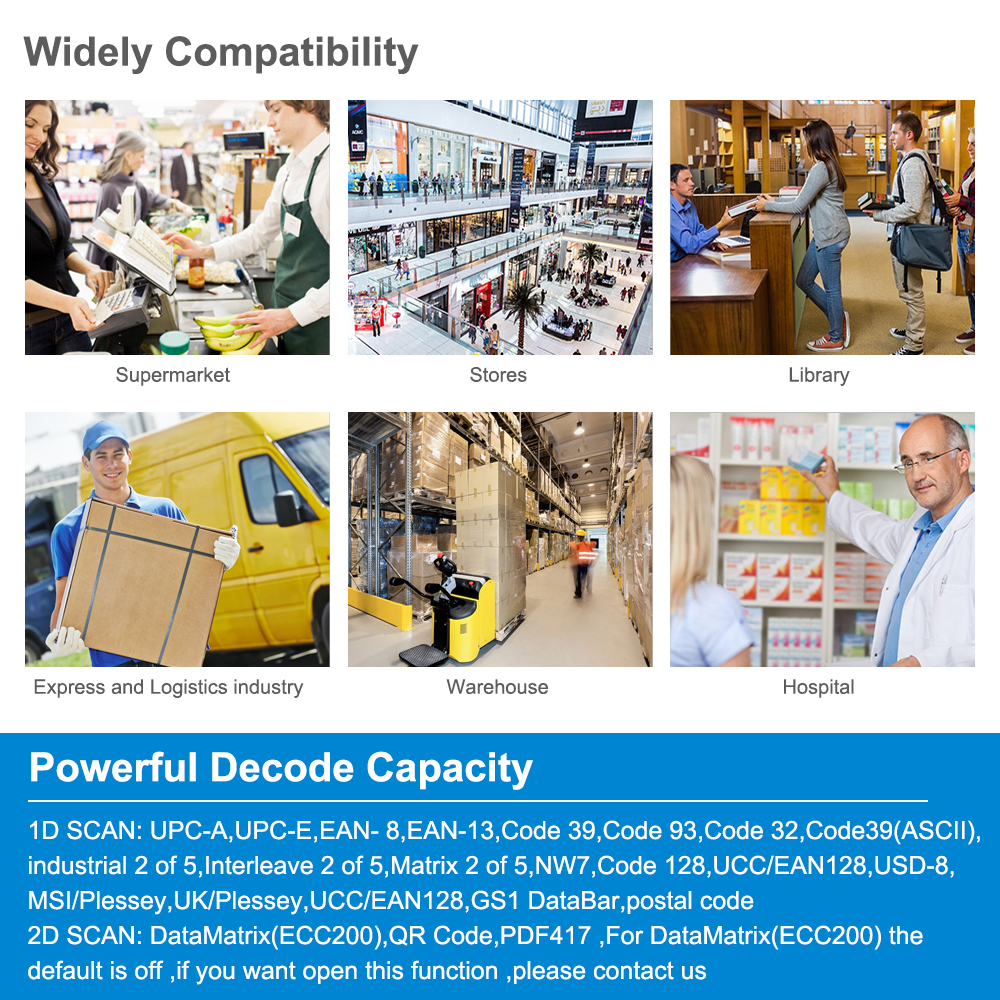

Based on usage scenarios, 2D barcode scanners can be categorized into several major types. By form factor, handheld 2D barcode scanners offer a comfortable grip and support mobile scanning, making them suitable for supermarket checkouts and warehouse inventory. Fixed scanners, mounted on a stand, can scan dozens of times per second, making them efficient in express delivery and production lines. Embedded scanning modules are compact and often integrated into smartphones and self-service payment machines. In terms of connection method, wired scanners are USB-powered, have low latency, and are suitable for fixed checkout counters. Wireless scanners rely on Bluetooth or Wi-Fi connections, with a transmission range of up to 10-50 meters, meeting the needs of scenarios such as large-scale warehouse inventory and outdoor logistics collection.

When selecting a 2D barcode scanner, it's important to consider four key technical parameters. The 2D barcode scanner's decoding capability is fundamental; confirm whether it covers mainstream 2D barcodes like QR codes and Data Matrix, as well as common 1D barcodes. A 2D barcode scanner's scanning speed directly impacts efficiency; high-speed models (e.g., 300 scans/second) are suitable for high-frequency production lines. Environmental adaptability is also crucial; an IP65 rating allows for outdoor use in humid environments, and a 1.5-meter drop resistance prevents accidental damage. The interface type must match the terminal device; USB is suitable for desktop work, while Bluetooth is suitable for mobile use. These parameters collectively determine the device's applicability and stability.

Today, 2D barcode scanners have permeated every aspect of life and industry. In retail, 2D barcode scanners scan QR codes on products to complete checkout or read payment codes to complete transactions. In logistics and express delivery, 2D barcode scanners scan QR codes on packages to quickly sort and track items, reducing human error. In industrial manufacturing, they recognize microscopic Data Matrix codes on parts to enable quality traceability. In government and healthcare, scanning QR codes on doctor appointments quickly retrieves medical records, and scanning vaccine barcodes allows for batch tracing. With its core value of replacing manual data entry, 2D barcode scanners have significantly improved information collection efficiency, becoming a crucial bridge connecting the physical world and digital systems, and driving the transformation of various industries towards intelligent and efficient operations.